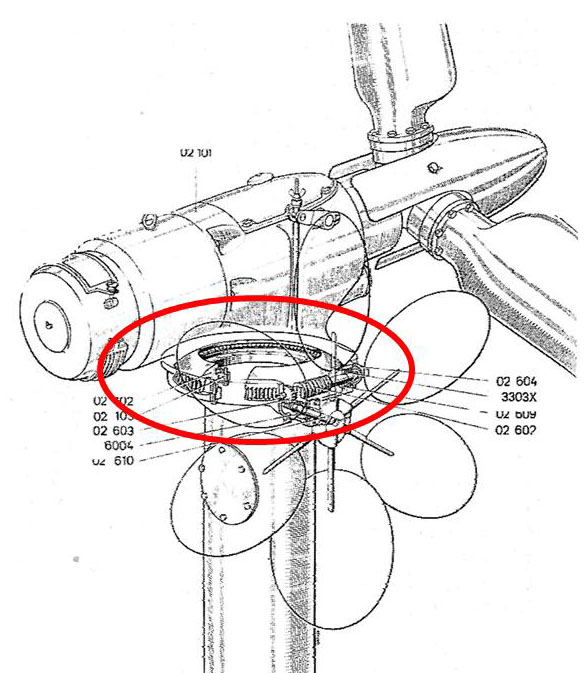

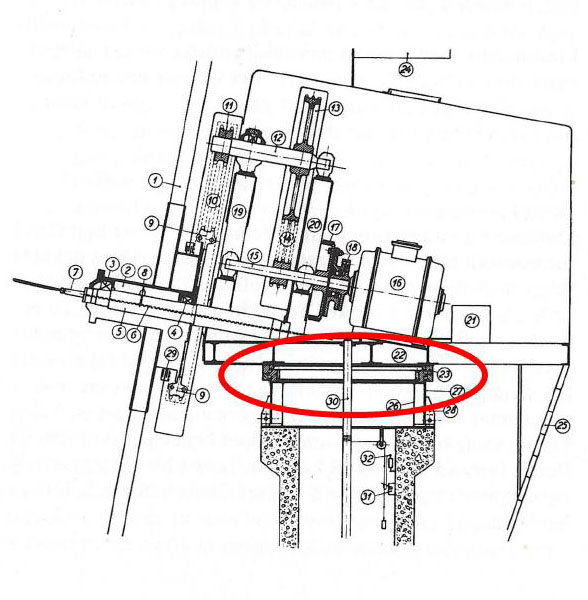

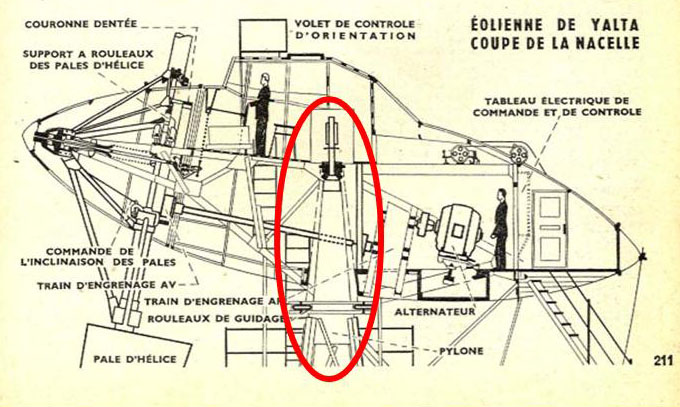

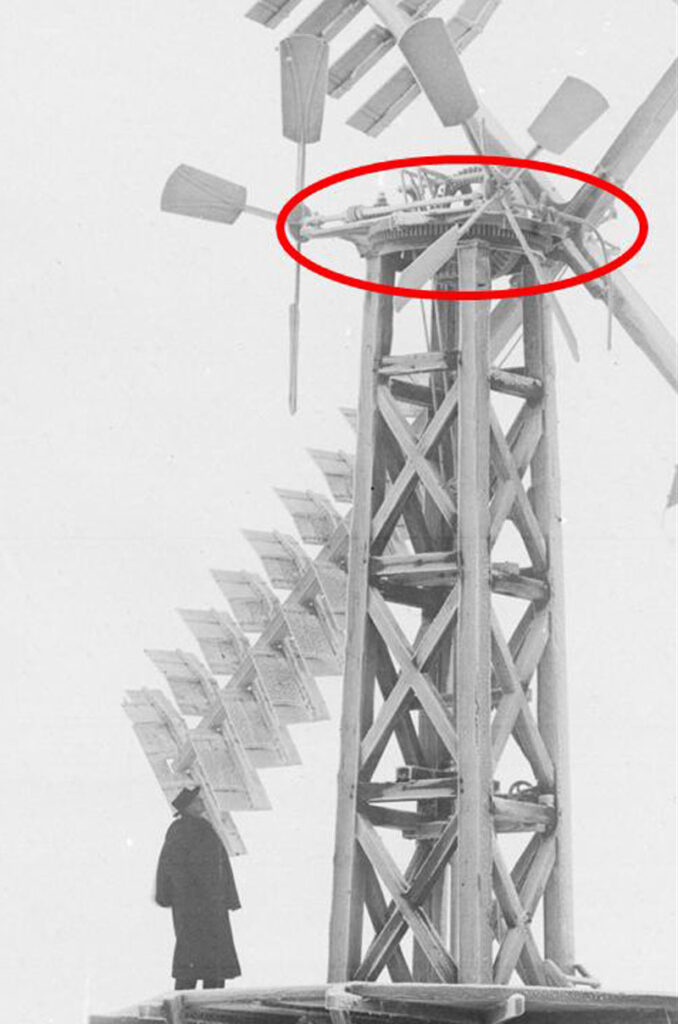

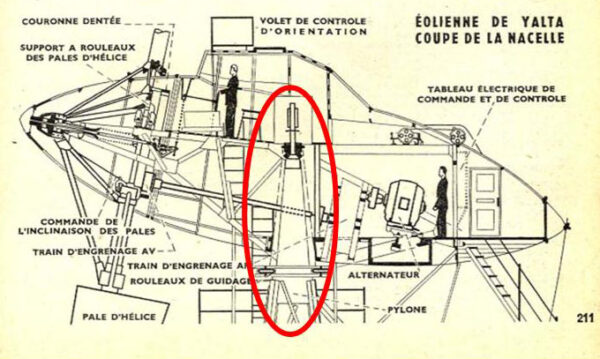

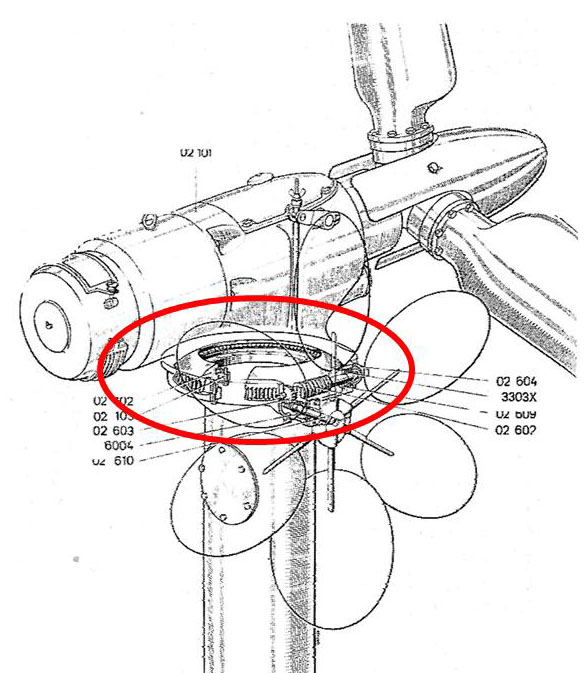

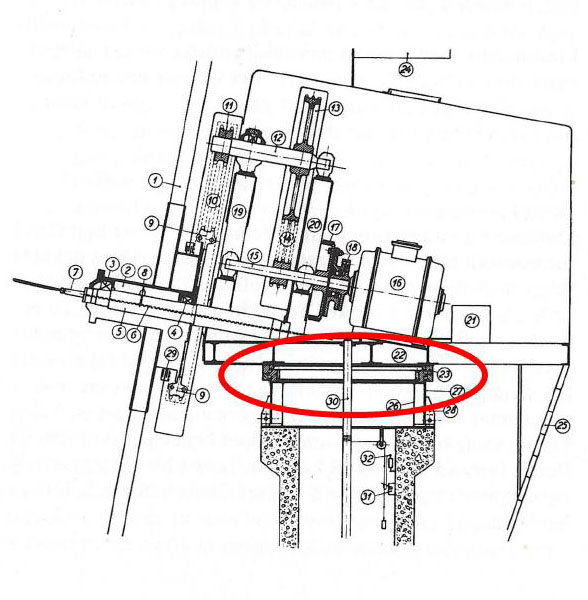

While researching material for an article on the 100 kW Soviet wind turbine at Balaklava, Etienne Rogier sent me an article with a cross section of the famous machine’s nacelle.[1] The cross section gives a rare glimpse into the workings of the machine and how it turned about the top of the tower in yaw—it used a pintle. I knew it was a pintle because I’d seen the same thing described in photos of Palmer Putnam’s wind turbine. I’d never given yaw bearings much thought before. Of course I’d written about the various ways wind turbines yaw, but never about the bearings—or bearing surfaces—that allow a wind turbine to face the wind smoothly while also keeping the machine on the top of the tower. Down another very deep rabbit hole I went.

Note: My thanks to Etienne Rogier, wind historian extraordinaire, for sending copies of rare documents my way.

Neither “pintle,” nor its sibling “kingpin,” are words we use today. No, the words we use to describe the device that allows the nacelle to yaw about the top of the tower to face the wind is slewing ring, yaw ring, or turntable. And therein lays a story about the evolution of modern wind turbines.

Today’s wind turbines use a large diameter ring or bearing upon which the wind turbine’s nacelle sits that allows the nacelle the freedom to turn toward the wind.

But it wasn’t always so. There were two different streams of technology to reach the same end. The other was the pintle.

Technological development seldom follows a straight line. There are often multiple paths to the same end, diversions, dead ends, and even the re-invention of previously discarded ideas. Few remember Sony’s Betamax, the one-time rival to VHS for analog video cassettes? And few remember that Nokia was once the world’s largest manufacturer of cell phones.

We see these various pathways today with all the “new” wind turbines that appear on the internet at regular intervals, wondrous machines that no one had thought of before. Unfortunately, nearly all had indeed been tried before and abandoned for one reason or other. Yet it’s a curse of the industry that these “inventions” continue to reappear.

The same is true with the pintle and the turntable. Despite widespread millwright knowledge of the turntable, the pintle continued to appear in wind turbine designs during the 1930s and well into the 1960s. The pintle was finally abandoned on large wind turbines only after Johannes Juul’s machine at Gedser in the 1960s.

What follows is a pictorial essay, organized chronologically. The topic awaits a professional historian to more thoroughly document early wind turbines and why their designers chose one technology over the other.

The story of the pintle or, in the case of blade pitch bearings, the kingpin, and its replacement by turntable bearings also applies to the hubs of wind turbines where the blades are attached. This is touched on briefly at the end.

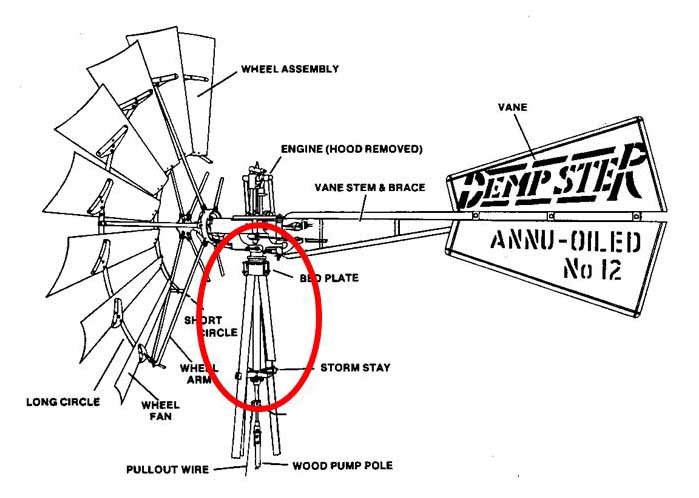

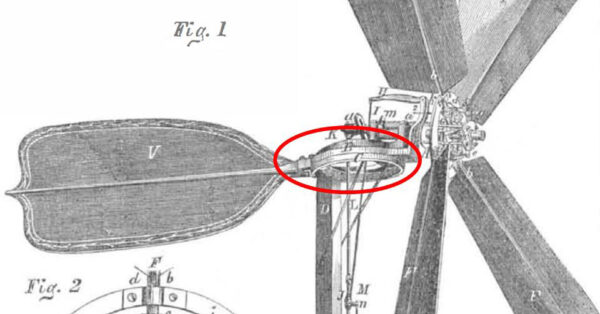

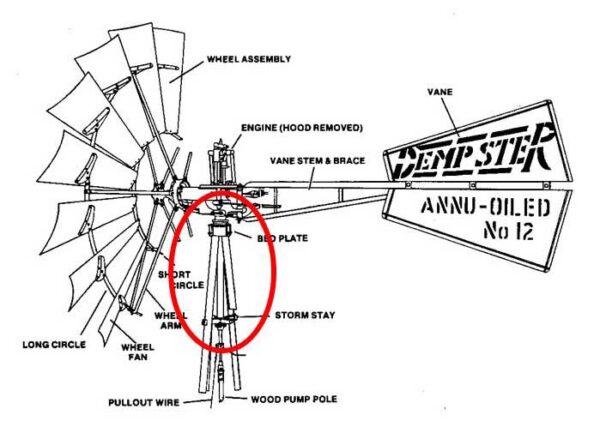

American Water-Pumping Windmills

I’d always associated the pintle with the North American water-pumping windmill, or “Chicago” mill if you prefer. It’s always used a pintle—or so I thought. I was wrong. Daniel Halladay’s original patent in 1854 for a self-regulating, water-pumping windmill used the equivalent of a turntable—and not a pintle.[2]

Subsequent Halliday windmills, and water-pumping windmills in general, used a pintle and continue to use the pintle to the present day.

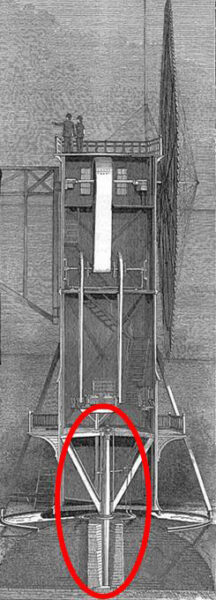

When Charles Brush built his mammoth wind “dynamo” for his Cleveland estate in 1888 he used a pintle or “post” buried deep into the ground. After all, his wind dynamo was nothing more than a glorified—and much enlarged–water-pumping windmill adapted to generate electricity.[3]

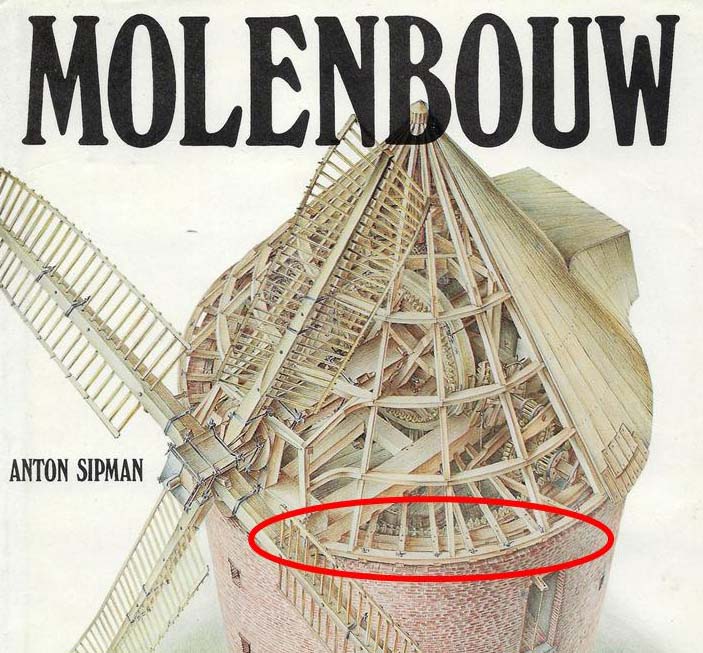

European or “Dutch” Windmills

With some notable exceptions, Europeans chose a different path. Europeans have a long history of working with the wind and their millwrights knew how to build windmills that would last for decades if not centuries.[4]

Europeans did use “posts” for their post mills. The “post” of the post mill is equivalent to a pintle or kingpin. However, they didn’t use pintles on their bigger mills.

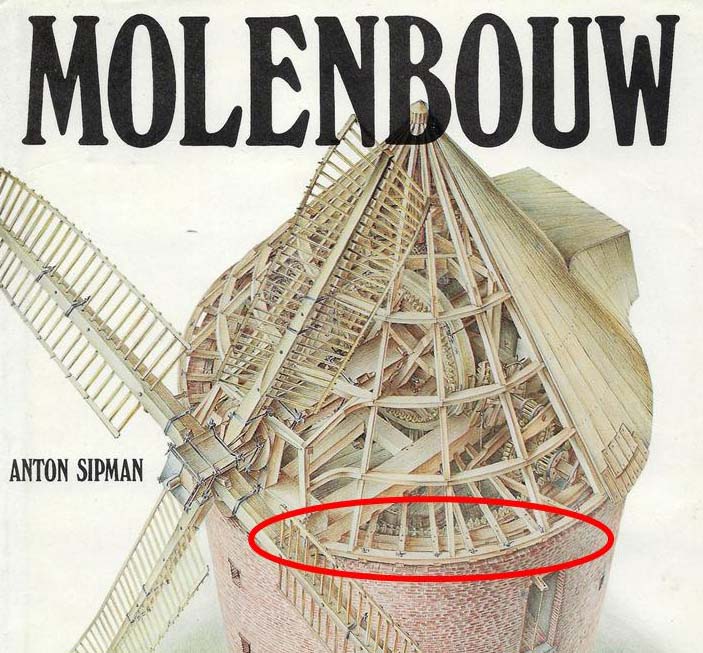

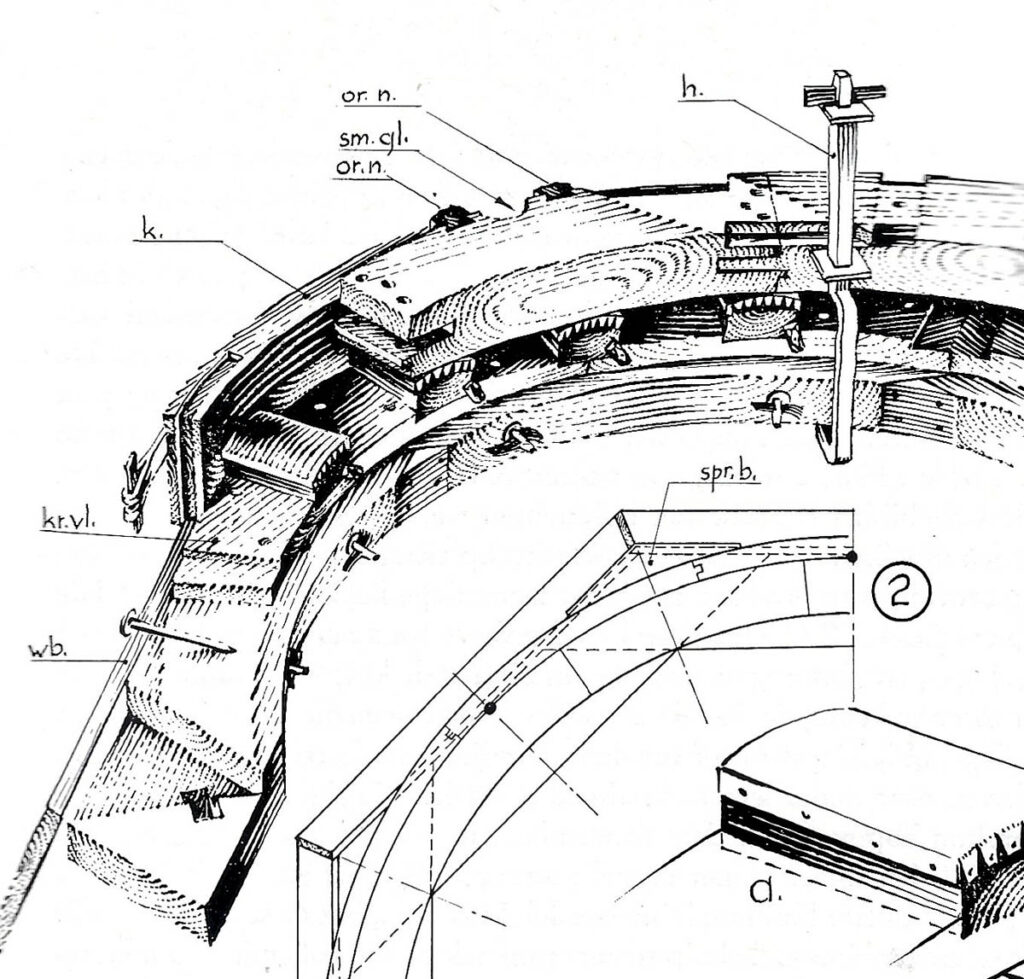

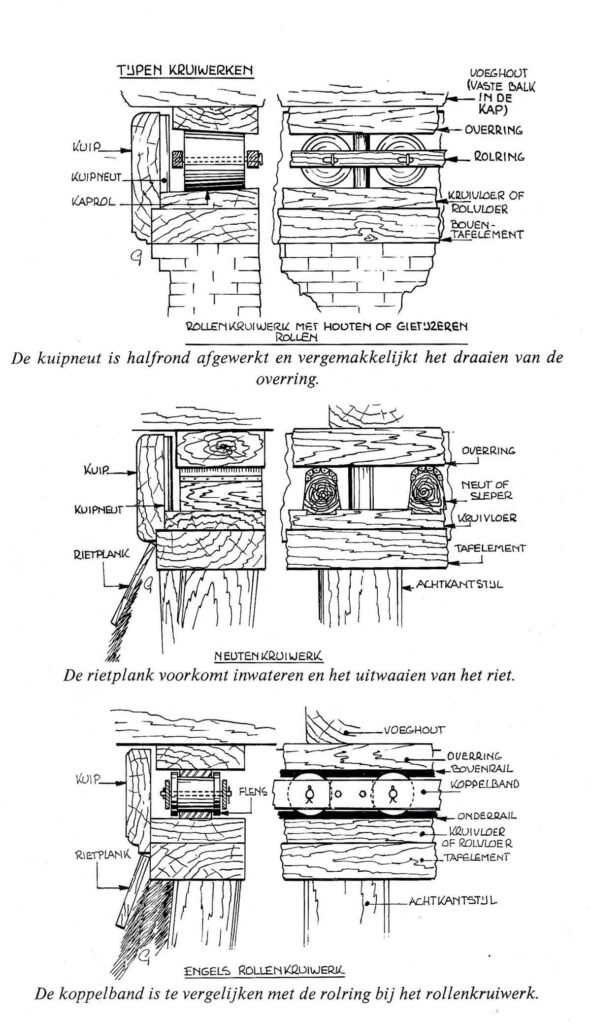

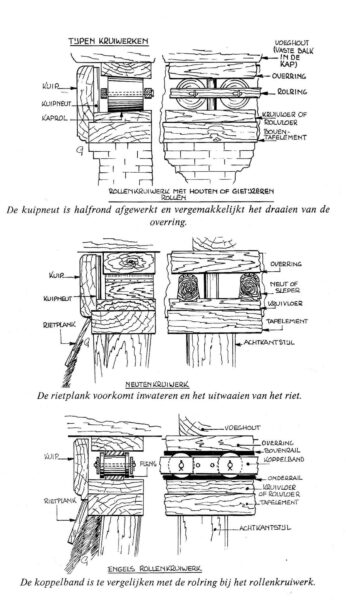

Their smock and tower mills used a large diameter ring that sat on a curb at the top of the tower. This freed up interior space of the tower for the milling machinery. These mills were typically much larger in diameter, and especially much taller, than post mills.[5]

There were various means to provide a bearing surface that would allow the “cap” of the windmill to turn to face the wind. Early windmills used lubricated sliding surfaces. Later windmills used roller bearings.[6]

For European wind turbine designers then, slewing rings were common millwrighting knowledge for large wind turbines.

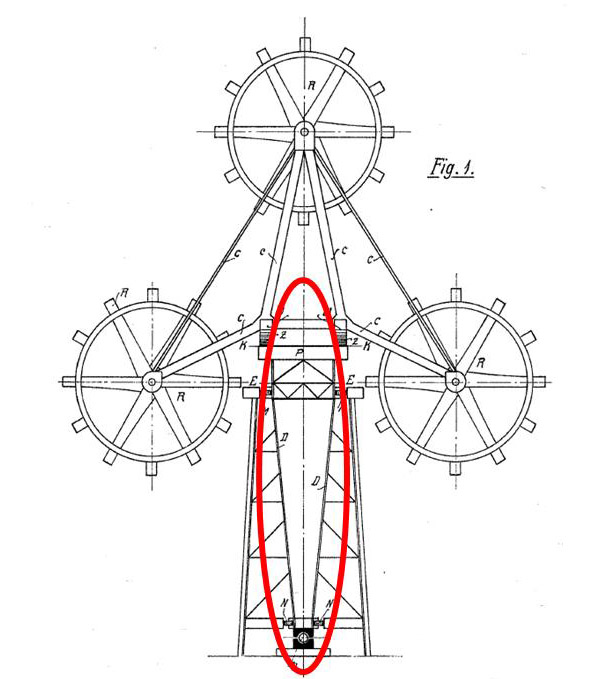

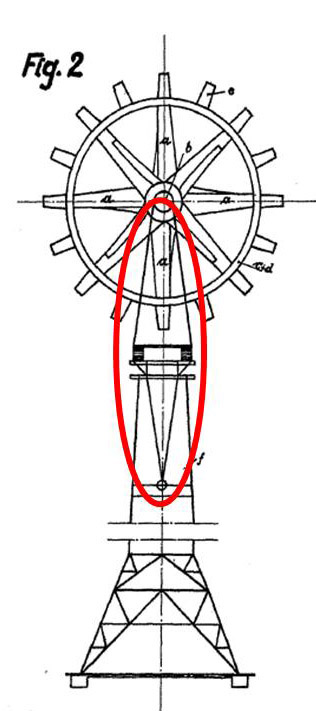

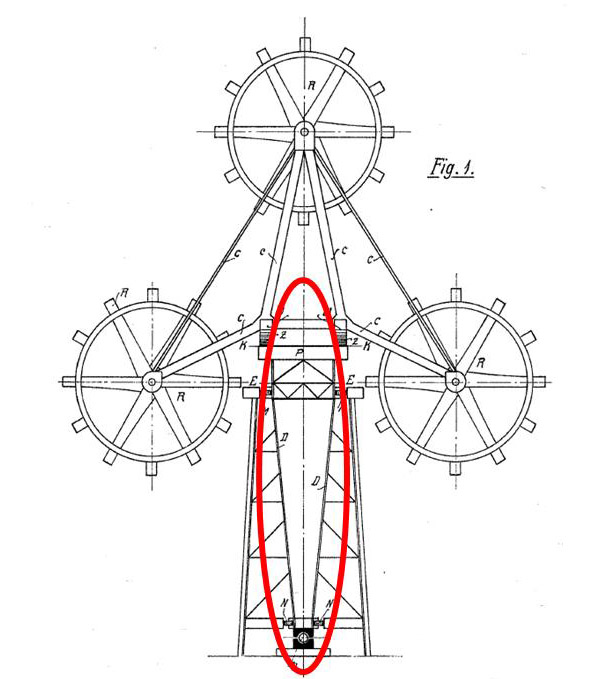

Hermann Honnef’s Pintles

One of those notable exceptions was Hermann Honnef, a dreamer and Nazi sycophant, who patented two concepts on wind turbines in 1931 and 1932.[7] Both patents included drawings that showed the use of pintles even though he must have been familiar with traditional European tower mills. Despite the patents, Honnef never built a wind turbine, his designs remained highly speculative.

1930s Soviet Designs Used a Pintle

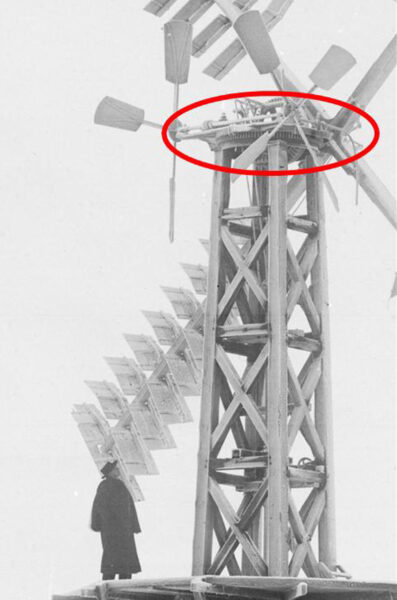

However, the Soviets did build a wind turbine at the time of Honnef’s patents. Considering what it takes to build any wind turbine from design to construction to operation, the Soviets must have begun in the mid to late 1920s.

Why Soviet designers chose a pintle over a slewing ring for their otherwise cleverly designed Balaklava turbine remains a mystery. The Soviet Union and its satellites had experience with traditional windmills, like their Western European counterparts. Their tower was massive enough that it could have supported a slewing ring. But for whatever reason, Soviet engineers chose a different path.

Designers of the 30-meter diameter Balaklava turbine knew what they were doing. They were equals of leaders in aerodynamics in Germany, France and Denmark and published in their respective journals. And they built a wind turbine that performed a practical task—feeding electricity into the Crimean grid to power a tram line from Balaklava to Sebastopol. It wasn’t only for research. It had to work and it did so, like Juul’s Gedser mill, for a decade until WWII. Startlingly, it was still standing—though inoperative–after the 1941-1942 siege of Sevastopol.

I haven’t found records of how much electricity the Balaklava turbine produced during its decade in service, but we do have documentation that one year it produced 279,000 kWh.[8]

The Balaklava wind turbine and its use of the Sabinin stabilizer that characterizes the variable-pitch design influenced subsequent Soviet wind turbines, including the VIME D-12 that was manufactured into the mid 1950s.[9] The D-12 also used a pintle.

1930s Windchargers

Throughout the 1930s several American manufacturers built windchargers for remote homesteads on the Great Plains. They were probably influenced by the ubiquitous Amercan water-pumping windmill and they too relied on the pintle.

Jacobs Wind-Electric, the most famous of the era’s windchargers, used a pintle. When Marcellus Jacobs re-introduced the wind turbine in the early 1980s, he reverted to what he knew best: a pintle.

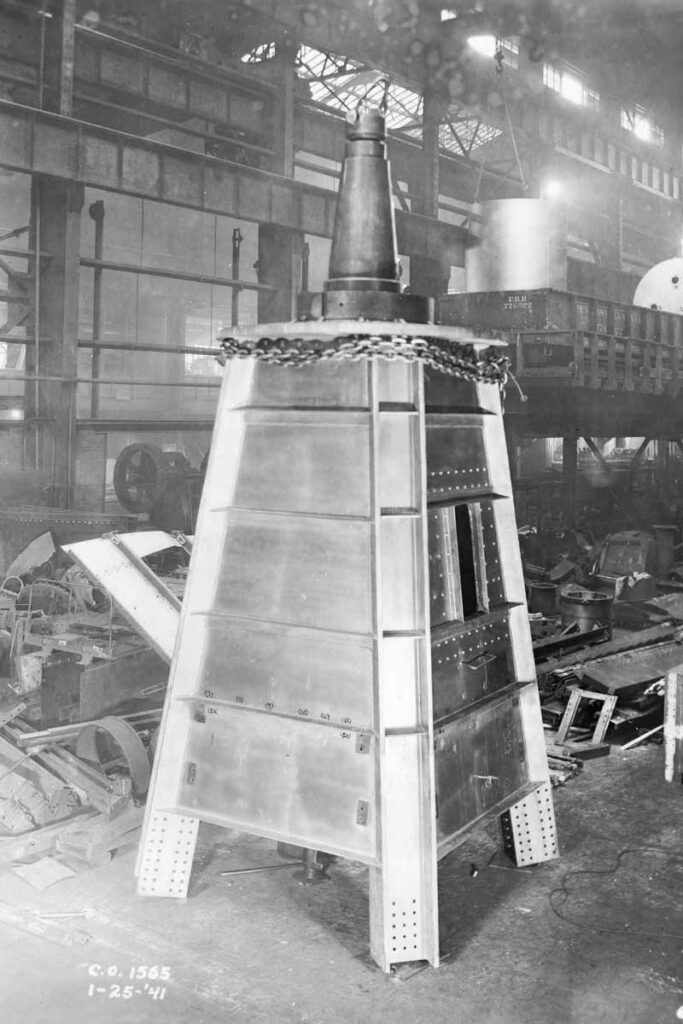

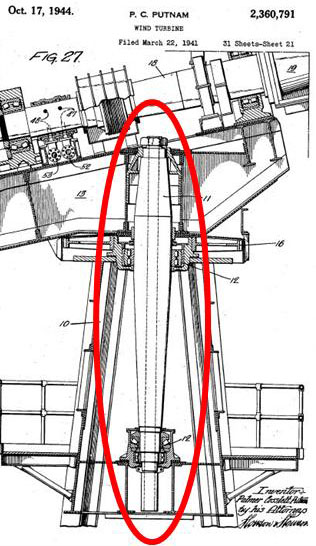

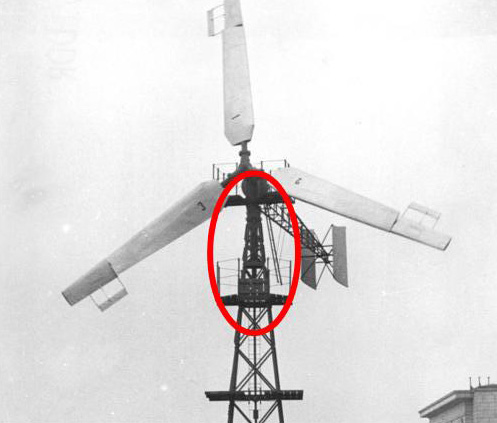

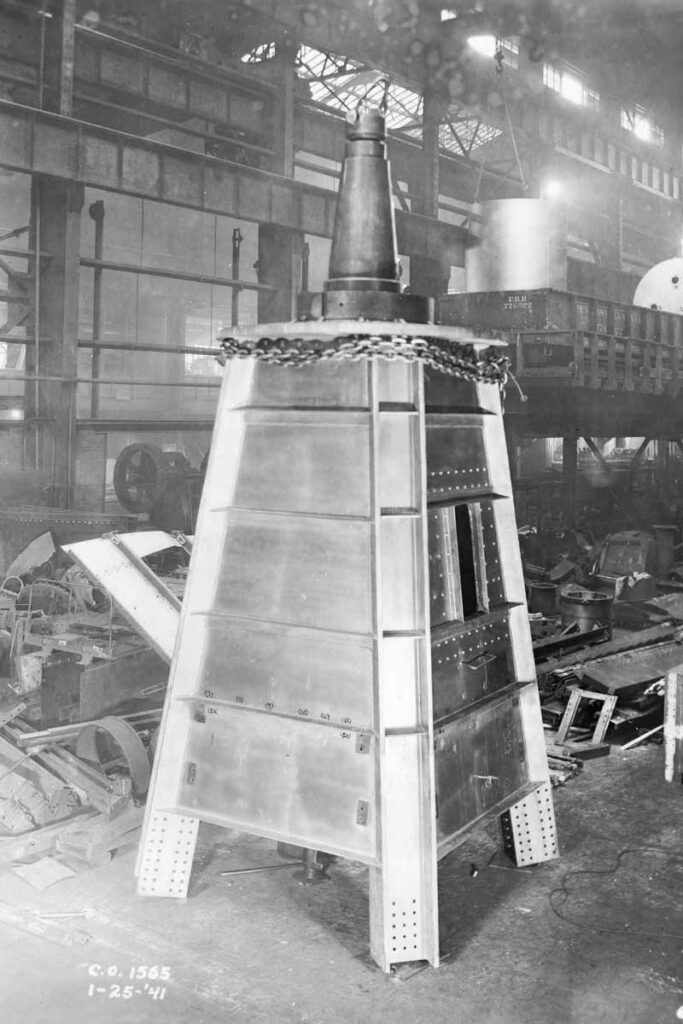

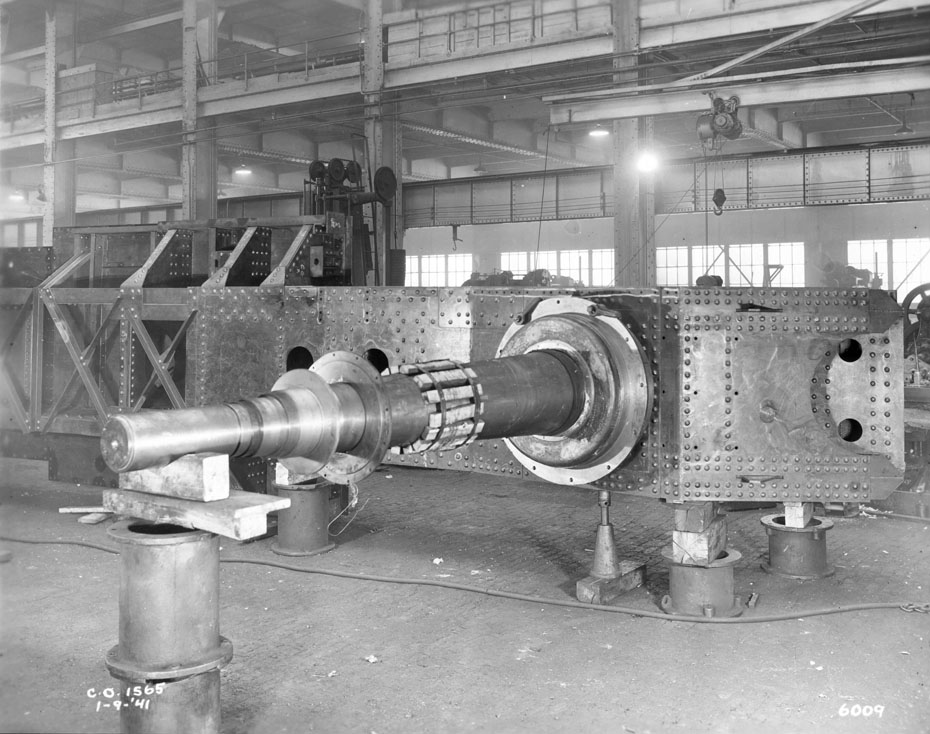

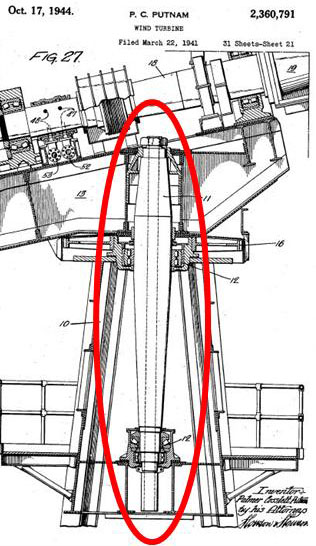

Putnam’s Pintle

In 1941 Palmer Putnam departed from previous millwright experience in the design of the famous Smith-Putnam wind turbine on Grandpa’s Knob near Rutland, Vermont. It used two blades, not three or four; it was downwind of the tower, not upwind; its blades used a constant plan form rather than twist and taper; the blades flapped rather than were fixed at the hub; and it used a synchronous generator instead of the cheaper and more widely available induction generator used on the Soviet’s Balaklava wind turbine.

Any one of these features in a new wind turbine design would have been challenging enough. Combining them into one wind turbine, and the world’s largest wind turbine for decades to come, was a recipe for disaster. It’s no surprise that the turbine eventually threw a blade.

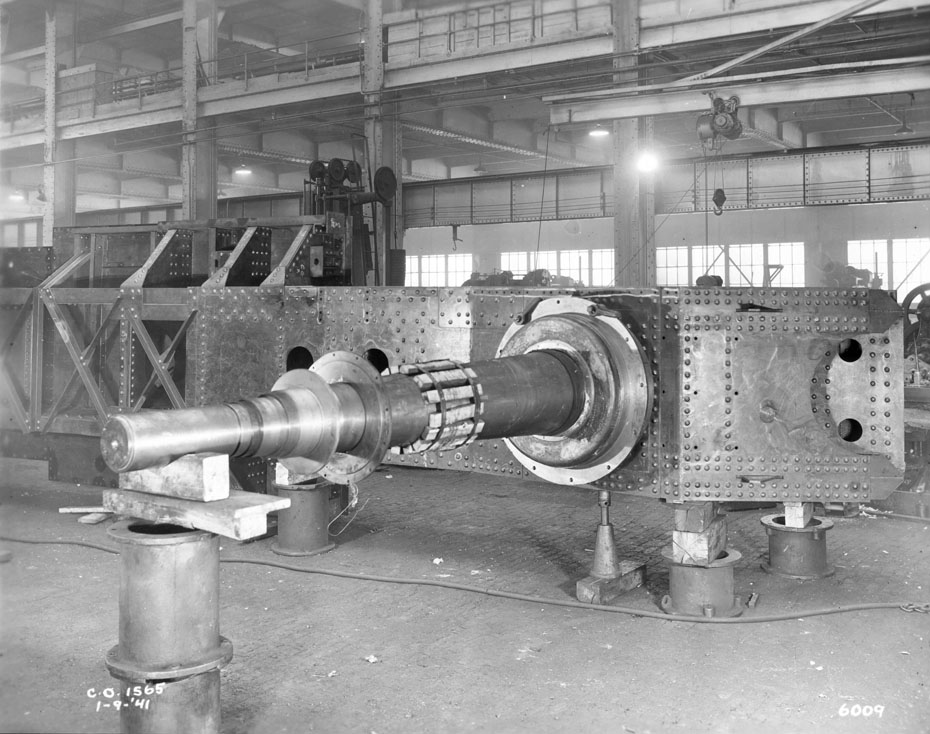

Here’s Putnam describing how he planned to build the pintle. That he never questioned whether to use a pintle or not seems apparent. He just presents the pintle as a fait accompli.

“The simplest solution for the pintle shaft and bearings seemed to be a large vertical pipe supporting the horizontally rotatable (yawable) structure aloft, and in turn supported by radial and thrust bearings in the upper tower structure.”[10]

Putnam’s pintle is one massive–and from the photos a solid–piece of steel. It can’t have been cheap.

Allgaier WE-10

Meanwhile in post war Germany, the team at Nordwind were designing wind turbines for remote locations. This team included Dimitri Stein and Ulrich Hütter. The photographic record isn’t sufficient to tell us what Stein used on his Nordwind design. However, Stein was familiar with Danish wind technology and in particular the Lykkegaard klapsejler design that used a slewing ring and yaw gear driven by two fan tails.

For his part, Hütter went on to design a commercial wind turbine for Allgaier, the WE-10, that used a slewing ring. Altogether, there were about 200 WE-10 units sold around the world. They ranged in capacity from 6-10 kW.

A few Allgaier WE-10s can still be found in Germany. I photographed one on a factory building near Holzhausen, Rheinland-Pfalz in 2005. From my photograph and a sketch in Heiner Dörner’s book on Hütter, it’s clear that Hütter designed the WE-10 to use a turntable. The sketch shows the yaw gear that’s driven by the side wheel or fan tail.[11]

From a photo of Hütter’s Schwabian Alps test site with his StGW-34 it appears that the StGW-34 also uses a turntable like that on the WE-10.

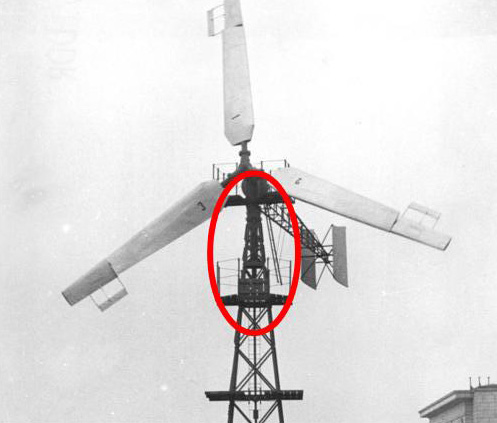

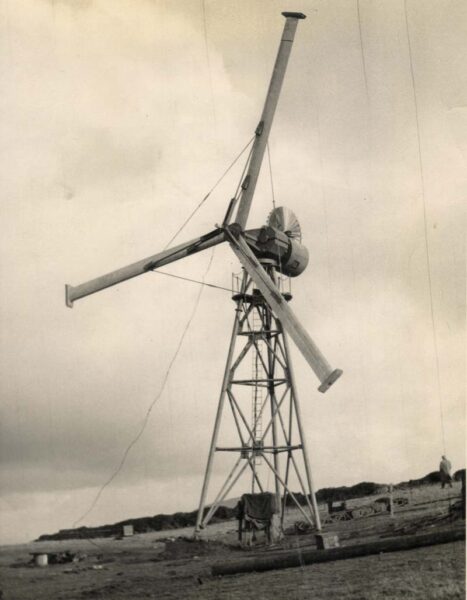

Pintle on the Isle of Man

The pintle seems like a costly choice for a large machine, such as Smith-Putnam’s 53 meter (175 feet) diameter wind turbine. It was also a poor choice for the 100 kW prototype turbine erected on the Isle of Man in 1959. The turbine for the Isle of Man was part of a series of three wind turbines in the post-war British wind program, one of which was the Enfield-Andreau pneumatic wind turbine, the other was the John Brown Engineering turbine on Costa Head, Orkney. Of the three, the Isle of Man design performed best.

We don’t know that the Isle of Man machine would have been more successful if it had used a turntable, but we do know that because it used a pintle it did fail.

“The test turbine experienced winds of more than 36 m/s in the standstill position without damage, “but after protracted unsupervised running, the machine ultimately failed, apparently by tilting about the pintle shaft to such an extent that one of the blades contacted the tower.” This ended the Isle of Man experiment on the 100 kW unit.[12]

John Brown Engineering

In a departure from the other pintle-led designs, it appears that John Brown Engineering’s venture used a yaw ring. I am not certain. The photographic record isn’t clear and the one engineering sketch on line is too indistinct to tell.[13]

Stills from two videos on line show a large diameter ring between the nacelle and the top of the tower. It’s not proof, but it’s the best we have to go on. To me, it looks like the John Brown’s Costa Head experimental unit used a turntable.[14]

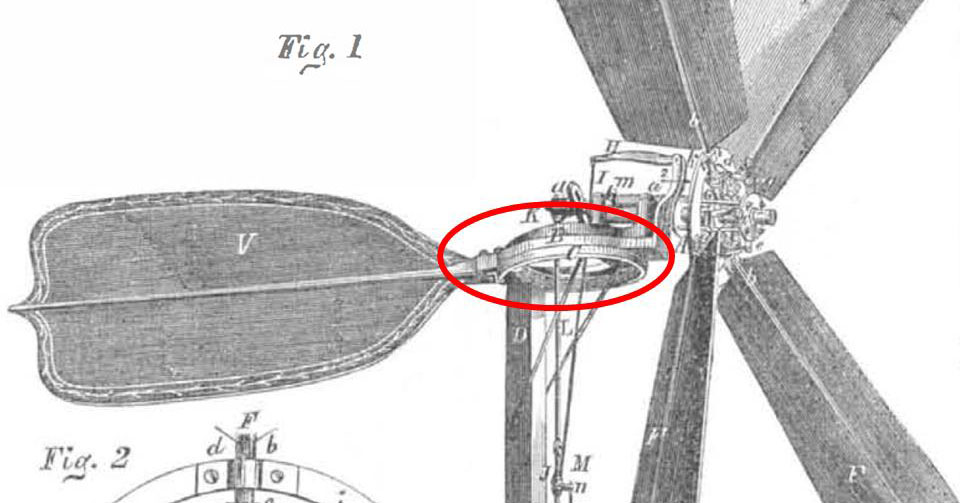

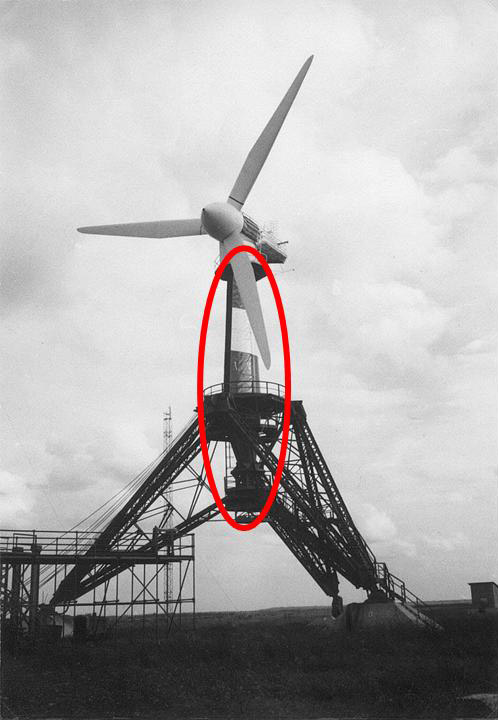

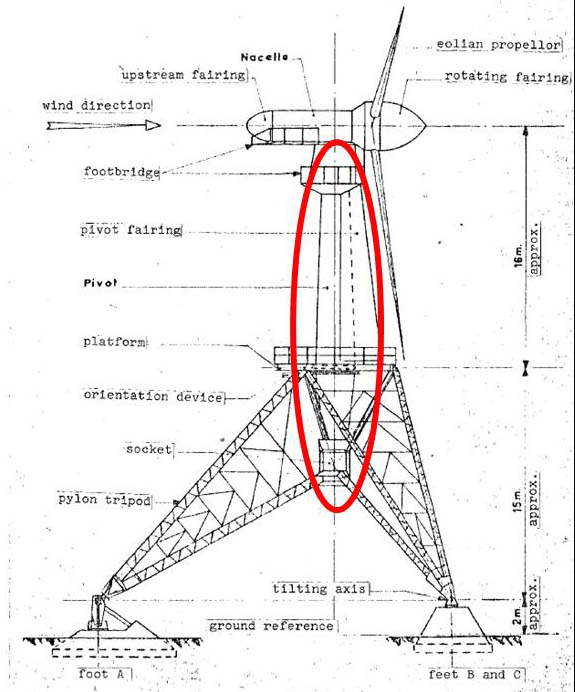

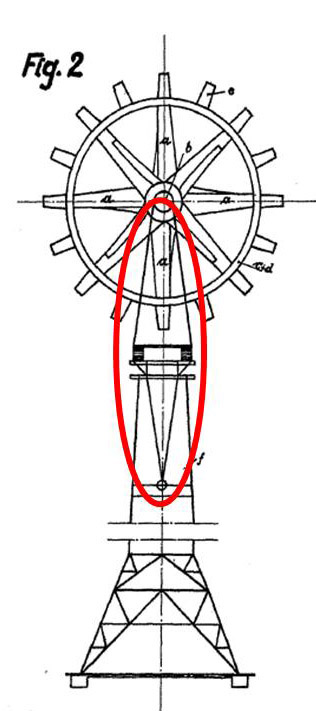

BEST-Romani

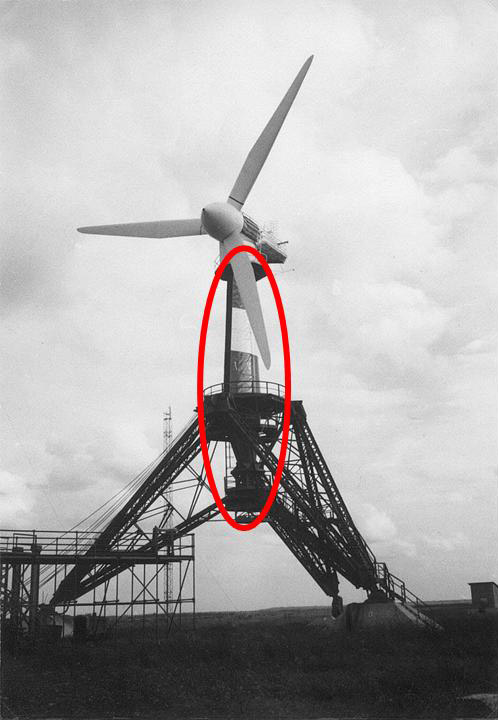

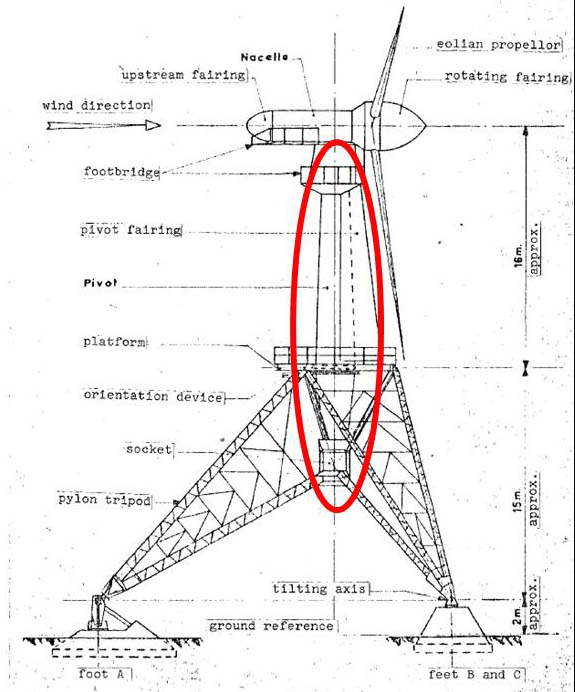

Lucien Romani’s BEST (Bureau d’Etudes Scientifiques et Techniques) is what we would call today a scientific think tank. Under contract to EDF, the French national electric utility in 1956, they sought to develop a wind turbine at Nogent-le-Roi, a low-wind site north of Chartres and west of Paris.

The BEST-Romani turbine was unusual in several aspects. The 30-meter diameter wind turbine was erected on a combination tubular tower atop a tripod truss. The tubular tower section included a fairing to minimize turbulence striking the three-blade downwind rotor. The faring yawed with the wind turbine in response to changes in wind direction.

Testing began in 1957 and the turbine operated sporadically from 1958 to 1963 when the stall-regulated turbine lost a blade.

Like Putnam, Romani used an enormous pintle. But unlike Putnam, the pintle, or pivotrie in French, was not a piece of solid steel. The 22-meter long pintle was rolled from sheet steel and welded into a tube. The pintle with its aerodynamic fairing weighed a massive 25 tons.[15]

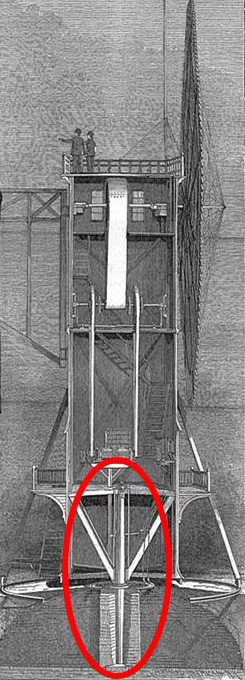

Klapsejler to Gedser

Danish foundries and metal-working shops had been building klapsejler windmills since at least the late 19th century. The Danish term klapsejler refers to the shutters on the blades that would clap shut when operating, opening in high winds or when the miller wanted to turn the machine off. The French called a similar construction jalousie shutters. Danish klapsejlers would sport four or five blades. All would use large diameter slewing rings at the top of the tower with a worm gear driven by dual fan tails. The most well known of the klapsejlers was the Lykkegaard brand that used four blades.

When Poul la Cour began experimenting with wind in 1891, he naturally turned to what was being used around him: a four-blade klapsejler with a slewing ring driven by two fan tails. This was the technology Danes were familiar with. It worked for them. When la Cour’s students, including one Johannes Juul, spread across Denmark to build their electricity-generating windmills, it was the klapsejler rotor and the slewing ring they took with them. This is what Johannes Juul knew worked.

This finally brings us to Johannes Juul’s mill at Gedser, or as the Danes call it, the “Mother Mill” because all Danish wind turbines are derived from it. Juul used a concrete tower as the materials for concrete are abundant in Denmark and Danes were skilled at using it.

The large diameter top of the concrete tower may have led naturally to the use of a large diameter slewing ring. Regardless, Juul was familiar with the slewing ring since his student days and he chose a slewing ring rather than a pintle and most large wind turbines since then have done the same.

There’s a cross-section in Jytte Thorndahl’s book on the Gedser mill illustrating how Juul’s wind turbine mated with the top of the concrete tower using a stub section. This stub includes the slewing ring and the slewing gear.[16]

Danish wind turbines introduced to California in the early to mid 1990s all used slewing rings following Juul’s Gedser design.

Variable-Pitch Bearings

A similar evolution from kingpins to large diameter turntables can be seen in pitch bearings. Early wind turbines like the Jacobs windcharger used kingpins, as did some early modern wind turbines. Vestas V23s were among the first Danish machines to use variable pitch blades and they used a kingpin. But Vestas quickly switched to turntable bearings.

When Mitsubishi introduced their 250 kW wind turbines to the Tehachapi Pass, the variable pitch blades used kingpins. I remember Jamie Chapman commenting on the Mitsubishi turbines near Mojave in the 1990s, “kingpins are dead,” he said. Chapman was a consulting engineer who had worked for US Windpower. At the time there were hundreds of Vestas V27s operating in the Tehachapi Pass. They used turntable bearings for the variable pitch blades and not kingpins. The Mitsubishi turbines were unusual in still using kingpins at that late date.

When Tehachapi’s Zond Systems introduced their own wind turbines in the late 1990s, their variable pitch rotors used turntable bearings as do all large wind turbines today.

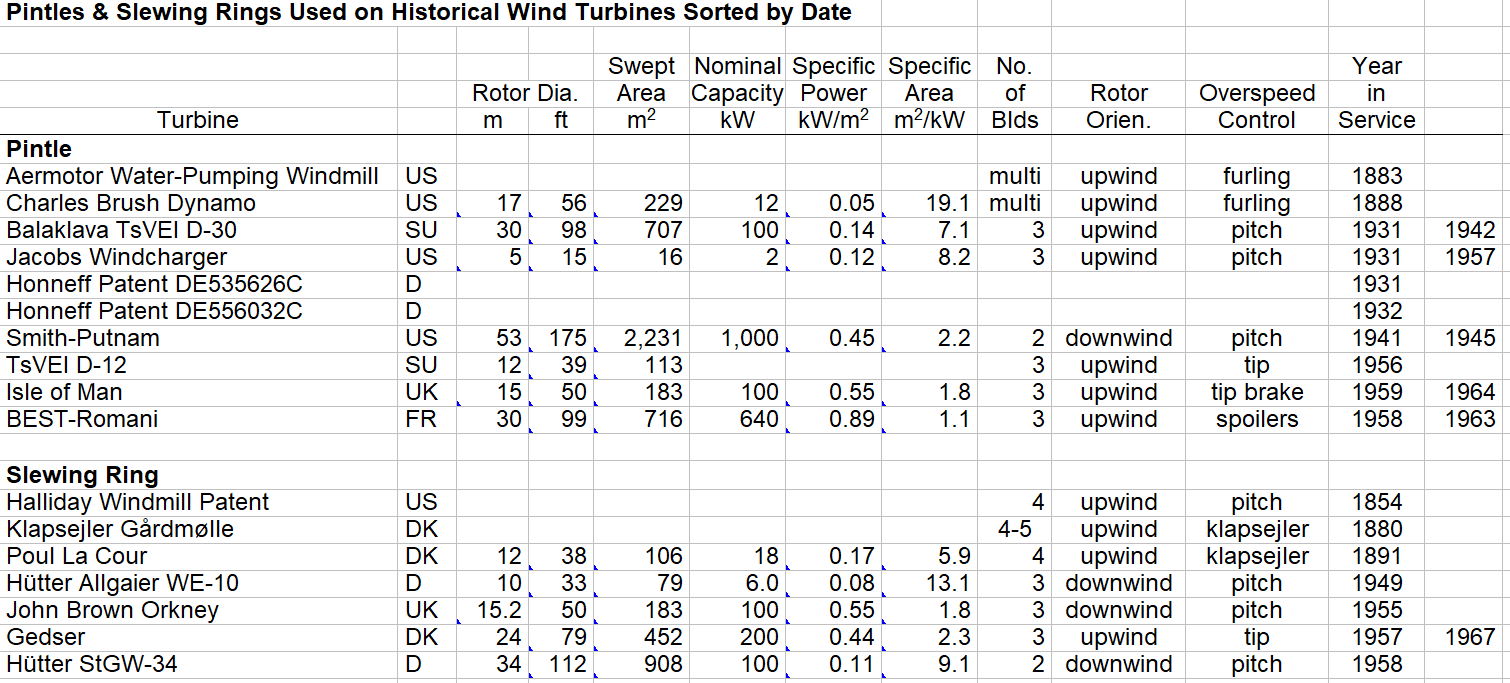

Chronological Summary of Pintles & Slewing Rings

[1] Andreau, Jean. “L’Éolienne Nouvelle Formule n’a ni Méchanisme ni Engrenage.” Science et Vie, avril 1950. This is the same Andreau of the Enfield-Andreau pneumatique wind turbine of the 1950s. This article describes Andreau’s invention.

[2] Scientific American. “Improved Governor for Wind Mills.” October 7, 1854. https://www.scientificamerican.com/issue/sa/1854/10-07/.

[3] Scientific American. “Mr. Brush’s Windmill Dynamo.” December 20, 1890. https://www.scientificamerican.com/article/mr-brushs-windmill-dynamo/.

[4] We’ll ignore the fact that European or “Dutch” windmills were also used in the colonies, though most were post mills.

[5] Sipman, Anton. Molenbouw: Het Staande Werk van de Bovenkruiers. De Walburg Pers Zutphen, 1975.

[6] Stokhuyzen, Frederick. Molens. Unieboek, 1981.

[7] Honnef, Hermann. Windmotor mit in entgegengesetzter Richtung umlaufenden Windrädern. Patentiert im Deutschen Reiche Patent DE535626C, filed März 1930, and issued September 24, 1931, and Honnef, Hermann. Windkraftmaschine mit einem zwei oder mehrere Räder aufnehmenden Rahmen. Patentiert im Deutschen Reiche Patent DE556032C, filed November 5, 1930, and issued July 14, 1932.

[8] Sektorov, V. R. “The Present State of Planning and Erection of Large Experimental Wind-Power Stations (Translation of ‘Sovremennoye Sostoyaniye Proyektirovaniya i Opytnogo Stroitel’stva Krupnykh Vetroelektricheskikh Ustanovok’).” Elektrichestvo, no. 2 (1933): 9–13. NASA Technical Translation F-15,512; April 1974.

[9] Fateyev, Ye. M. Wind Engines and Wind Installations (Translation of ’Vetrodvigateli i Vetroustanovki). Moscow, State Publishing House of Agricultural Literature, 1948. NASA Technical Translation F-16170; March 1975. See Fig. 142. http://archive.org/details/nasa_techdoc_19750014832. And Zimmerman, Peter. Windmotor D-12. 1956. Black & White Photo. Bundesarchiv. https://commons.wikimedia.org/wiki/File:Bundesarchiv_Bild_183-36400-0340,_Leipzig,_Fr%C3%BChjahrsmesse,_Windmotor_D-12.jpg.

[10] Putnam, Palmer Cosslet. Power from the Wind. Reprinted 1974. Van Nostrand Reinhold, 1948, page 114.

[11] Dörner, Heiner. Drei Welten—Ein Leben: Prof. Dr. Ulrich Hütter. H. Dörner, 1995, page 222.

[12] Elliott, D.E. “Economic Wind Power.” Applied Energy 1 (1975): pp 167-197. https://doi.org/10.1016/0306-2619(75)90033-1.

[13] Orkney Sustainable Energy Ltd. “Costa Head Experimental Turbine.” 2020. http://www.orkneywind.co.uk/costa.html.

[14] BBC. “BBC Archive 1951: Experimental Orkney Wind Power.” May 23, 2024. https://www.bbc.com/videos/cj55r8ynglqo. And Costa Head Wind Turbine Video. 2019. Scottish Screen Archive. https://www.youtube.com/watch?v=3eU6jFEya84.

[15] Service Des Etudes et Recherches Hydrauliques, Division Energie du Vent. Experimental Aerogenerator Type B.E.S.T. – Romani Description, Assembly, Test Program. May 1958, 54. NASA Technical Translation F-15,037; August 1973.

[16] Thorndahl, Jytte. Gedsermøllen: den første modene vindmølle. Elmuseet, 2005. Page 67.